Increase Efficiency With MeiXin Brush Machinery Automation

In today’s highly competitive manufacturing industry, efficiency and precision are more critical than ever. Companies are continuously seeking innovative ways to streamline production, reduce labor costs, and maintain consistent product quality. MeiXin Brush Machinery automation provides an ideal solution, enabling manufacturers to maximize output while minimizing operational challenges.

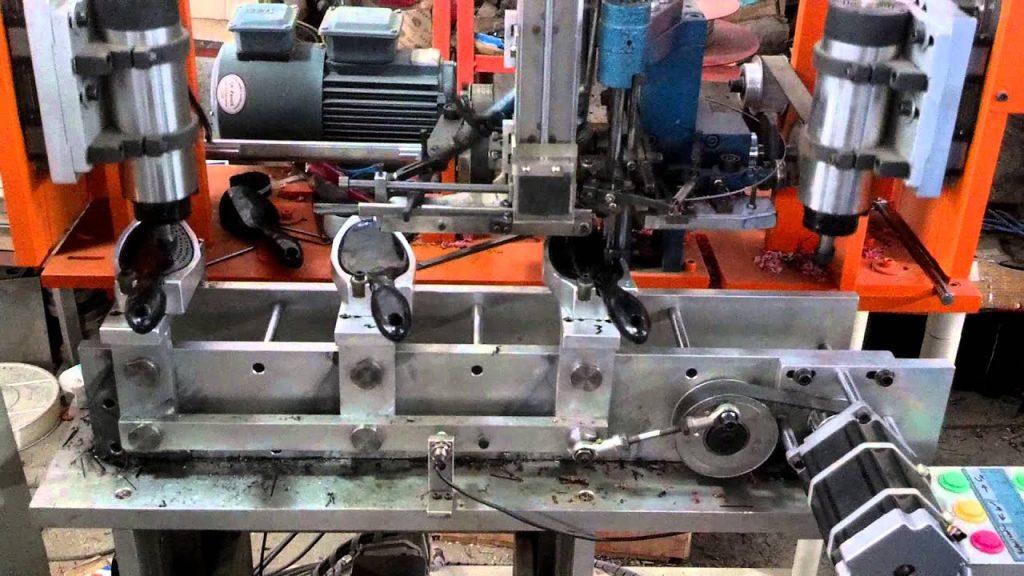

Introduction to MeiXin Brush Machinery Automation

Automation in brush production is transforming the way companies operate. MeiXin Brush Machinery automation integrates advanced technology with practical design, allowing manufacturers to produce high-quality brushes with greater speed and accuracy. By leveraging these systems, businesses can enhance productivity and stay ahead in an increasingly demanding market.

Benefits of Automation

Investing in MeiXin Brush Machinery automation provides multiple benefits:

- Faster Production Cycles: Machines can operate continuously with minimal human intervention.

- Consistent Quality: Automated systems reduce human error, ensuring uniformity across all products.

- Reduced Labor Costs: Automation decreases dependence on manual labor.

- Scalability: Production lines can be expanded or upgraded to meet growing demand.

By adopting MeiXin Brush Machinery automation, manufacturers gain a competitive advantage, improving efficiency and product consistency simultaneously.

Key Features of MeiXin Brush Machinery Automation

Understanding the features of MeiXin Brush Machinery automation helps manufacturers maximize its potential. These systems are designed to enhance performance, reduce downtime, and provide precise control over the production process.

Precision Engineering

MeiXin Brush Machinery automation ensures high-precision operations across all production stages. This precision minimizes material waste, reduces defects, and maintains consistent quality, which is crucial for meeting industry standards.

Advanced Control Systems

The machines feature intelligent control systems that allow operators to monitor and adjust production in real-time. Parameters such as speed, brush length, and bristle density can be precisely set, ensuring optimal results for every batch.

Versatility in Brush Types

MeiXin Brush Machinery automation can handle a wide range of brushes, including:

- Household cleaning brushes

- Toothbrushes

- Industrial brushes

- Specialty and custom brushes

This versatility allows manufacturers to diversify their product lines without the need for multiple machines.

Energy Efficiency

Energy-efficient components in MeiXin Brush Machinery automation reduce operational costs while supporting sustainable manufacturing practices. By lowering electricity consumption, businesses can save money and reduce their environmental impact.

Applications of MeiXin Brush Machinery Automation

MeiXin Brush Machinery automation is suitable for various industries, providing efficiency and precision in every application.

Household and Personal Care Brushes

Automated systems are ideal for producing toothbrushes, brooms, mops, and other household brushes. Automation ensures uniform quality, faster production, and consistent output to meet consumer demand.

Industrial Cleaning Brushes

Industrial sectors require heavy-duty brushes that can withstand rigorous use. MeiXin Brush Machinery automation produces these brushes efficiently, meeting high standards for durability and performance.

Specialty Brushes

Automation allows for customization, enabling manufacturers to create brushes with specific shapes, sizes, and materials for niche markets such as medical, cosmetic, or technical applications.

How MeiXin Brush Machinery Automation Improves Productivity

Automation significantly enhances productivity by streamlining operations and reducing human error. Key improvements include:

Faster Production Speeds

Automated machines operate continuously, drastically increasing production capacity compared to manual methods.

Reduced Labor Dependence

By minimizing the need for manual labor, MeiXin Brush Machinery automation lowers workforce costs and reallocates employees to higher-value tasks.

Consistent Product Quality

Automation ensures that every brush meets exact specifications, reducing defects and maintaining brand reputation.

Minimized Downtime

Smart systems with automated monitoring detect potential issues early, preventing machine failures and reducing production interruptions.

Maintenance and Support

Proper maintenance is essential to maximize the longevity and efficiency of automated machinery. MeiXin Brush Machinery provides:

- Detailed operation manuals

- Routine maintenance schedules

- Technical support and guidance

Regular maintenance ensures machines remain reliable, efficient, and safe for operators.

Safety Considerations

Safety is a critical concern in automated production. MeiXin Brush Machinery automation incorporates safety features such as emergency stop buttons, protective covers, and automatic alerts to prevent accidents and ensure a secure working environment.

Real-World Success Stories

Manufacturers who have implemented MeiXin Brush Machinery automation report measurable improvements in productivity and cost savings.

Example Case

A medium-sized brush manufacturer upgraded its production line with MeiXin Brush Machinery automation. Within six months, production speed increased by 40%, labor costs dropped by 25%, and product quality remained consistently high. This demonstrates the tangible benefits of adopting automation in brush production.

Conclusion

MeiXin Brush Machinery automation is transforming the brush manufacturing industry by improving efficiency, consistency, and scalability. With precision engineering, versatile applications, energy efficiency, and advanced control systems, these machines help manufacturers meet growing demand while maintaining superior product quality. Investing in MeiXin Brush Machinery automation is a strategic move for businesses seeking to boost productivity, reduce costs, and stay competitive in the modern manufacturing landscape.